Halos and Angel Eyes

Angel Eyes, also known as "halos," are accessory lights that are installed or integrated into a vehicle's headlight assembly, to encircle the low or high-beam headlight. They do not replace the headlight or any other lights, they are simply accessory lights, for cosmetic purposes, or to be used as a DRL.

Originally designed and first used by BMW, the unique look was desired by many in the aftermarket community, leading to a surge of lighting components available to be installed into existing headlights to create the same look. There any many different types of angel eye components on the market, utilizing different technologies to create the "ring of light" effect. Continue reading below to learn more about Angel Eye technology.

Table of Contents

Optical LED

The most basic angel eyes are made up of a clear acrylic rod. The rod is heated so it becomes pliable, and is shaped into a circle of the correct diameter for the application. Then, it is notched at even points along the ring. Finally, two traditional 5mm LEDs are inserted at the ends, shining light into the ring and being directed outwards at every point there is a notch. The overall effect is small lines of light in a circular pattern, depending on how many notches there are on the ring.

These rings are available in a number of colors- you just need the right LED, and the correct ring size. You can even use four-lead RGB 5mm LEDs to create multicolor effects. They are extremely durable, and should last a very long time, but they are somewhat unrefined, as the "notching" process is often accomplished with a rotary tool, such as a dremel.

However, the rings are very low in brightness, due to the fact that they use only two LEDs. Total lumen output is only around 10 lumens, so they are not visible during the day, and only provide a faint glow at night. Additionally, the light can be uneven. The part of the ring closest to the LEDs is usually a bit brighter than the opposite side from the LEDs, as brightness is immediately lost as the light makes its way through the ring.

Originally, many automotive enthusiasts crafted these by hand, but due to better options, very few are handmade in this way anymore, or offered individually for sale. You'll still find this type integrated into many fog lights and headlights, as they are extremely cheap to make. However, if you want your angel eyes to be visible, it's best to use a newer technology.

CCFL

Cold cathode florescent light, or CCFL, was the next widely-available light to be used for angel eyes. This is essentially a florescent light, like you'd find in an office, but it is very small, and shaped into a ring. Florescent light runs much better on AC power, and requires high voltage to maintain an electrical arc of light, so small inverters are required to power each ring. It is important that these inverters are fully waterproof and high in reliability.

Since it is a florescent light, the output is a very even, smooth light, with only a break on one side where the electrodes are attached for power.

The rings themselves are extremely reliable, and last for thousands of hours, but since they are glass, they can be very fragile. Many CCFLs are designed with diffusing protective covers on them, in order to decrease the chance of damage. This cover creates a "thicker" ring of light as well, versus the thin ring of the actual CCFL. As a result, this provides two distinct looks that are available.

Cool white is the most common color, and is a nice 5000K color temperature for most rings on the market. Because other colors are created using a fluorescent phosphor layer, these other CCFL colors are "washed out," so it is difficult to achieve a true, deep red or amber color. Instead, you might end up with more of a pink and warm white. CCFL rings cannot be multicolor.

SMD LED

Surface-mount LEDs are the next step in the LED lighting arena. Due to their smaller size, they can be mounted onto a circular board, facing directly forward. This provides an extremely high light output in the forward direction, while maintaining a reasonable cost, with SMT manufacture.

SMD LED rings require very low power for operation, which makes them convenient to use and install. Often, they are dimmable as well.

There are many styles of SMD Angel Eye rings available, based on the number of LED chips on the ring, or its density, and the size of the chips themselves. The LED chips most commonly used are 3528 and 5050.

Diffusing Covers

SMD LEDs designed in a circle will create a dotted-ring effect, as each LED creates an individual dot of light. Many enjoy this look, as it provides a unique appearance. However, those who want a more uniform, solid circle of light can add a diffusing cover, which is designed to fit over the SMD LED ring and diffuse the light, to make it appear more uniform.

COB

COB, or chip-on-board, is a manufacturing technology of LEDs where the LED chips are mounted directly to a PCB board. Essentially, the whole board becomes the LED package, and in white rings, the converter layer covers the whole surface, diffusing the light very evenly from each LED chip. Multicolor COB technology is not possible at this time.

This results in a very uniform and very bright light source. There is much less surface area to diffuse heat compared to the heatsinking of individual LEDs like on an SMD LED, so the heat should be diffused through a sturdy aluminum backing. Many cheaper rings use an aluminum-colored film on the back, not actual aluminum.

There are no resistors on the ring itself, rather, the power is supplied at a constant current through an external regulator, which is then plugged into a 12V source.

The white color appears completely yellow when off, which can be mitigated through the use of diffusing covers. Many COB rings now utilize an extra white-colored layer on top of the phosphor layer, to make the white-colored rings also appear white when they are off.

COB rings do exist that are RGB multicolor, but currently, none exist that use a diffusing layer to combine the colors, leading to a subpar dotted effect on lower-intensity colors such as red. The addition of a diffusing layer creates extra heat buildup, which reduces the lifespan. Many compnies are actively offering a non-diffused RGB COB ring, and other companies, including Diode Dynamics, are researching a diffused, but reliable RGB COB ring.

Resisted vs Regulated SMD LED

The most common method of designing surface-mount LED rings is with resistors mounted directly to the ring, in order to control power going to the LEDs on the ring. Usually, one resistor is used for three LEDs.

This method is quite reliable, but under certain conditions, the resistors on the ring itself can be subjected to excess heat, especially when in proximity to headlights. This stresses the resistors. Additionally, automotive circuits can occasionally spike in voltage, also adding stress to the resistors. Over time, with ongoing stress, the resistors can fail or only work intermittently in some applications, especially those where there is more heat near the ring.

Diode Dynamics has progressively improved the durability of the resistors on the rings, leading to much higher reliability. However, due to the sheer number of resistors on each ring, especially in RGB rings, and the inability to fully predict the conditions of use of each ring, there are still failures from time to time.

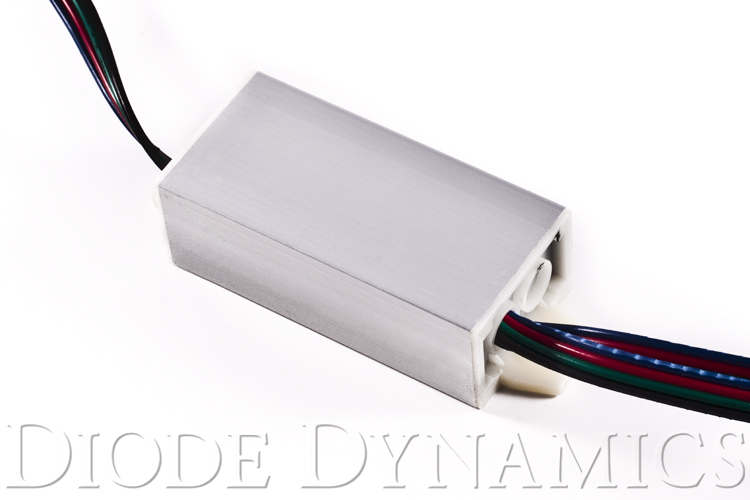

In order to eliminate the problem completely, Diode Dynamics has developed LED rings that do not utilize any resistors on the ring itself. Only the SMD LEDs are on the ring.

The power is controlled instead by voltage regulators, which are less susceptible to voltage swings and heat. They are housed in a small, fully-potted (waterproof) regulator box, which is simply attached inline between the power source or controller, and the LED ring. This method is still completely plug and play, but provides extremely high levels of reliability. And now, more LEDs can be put on each ring, making them brighter, too!